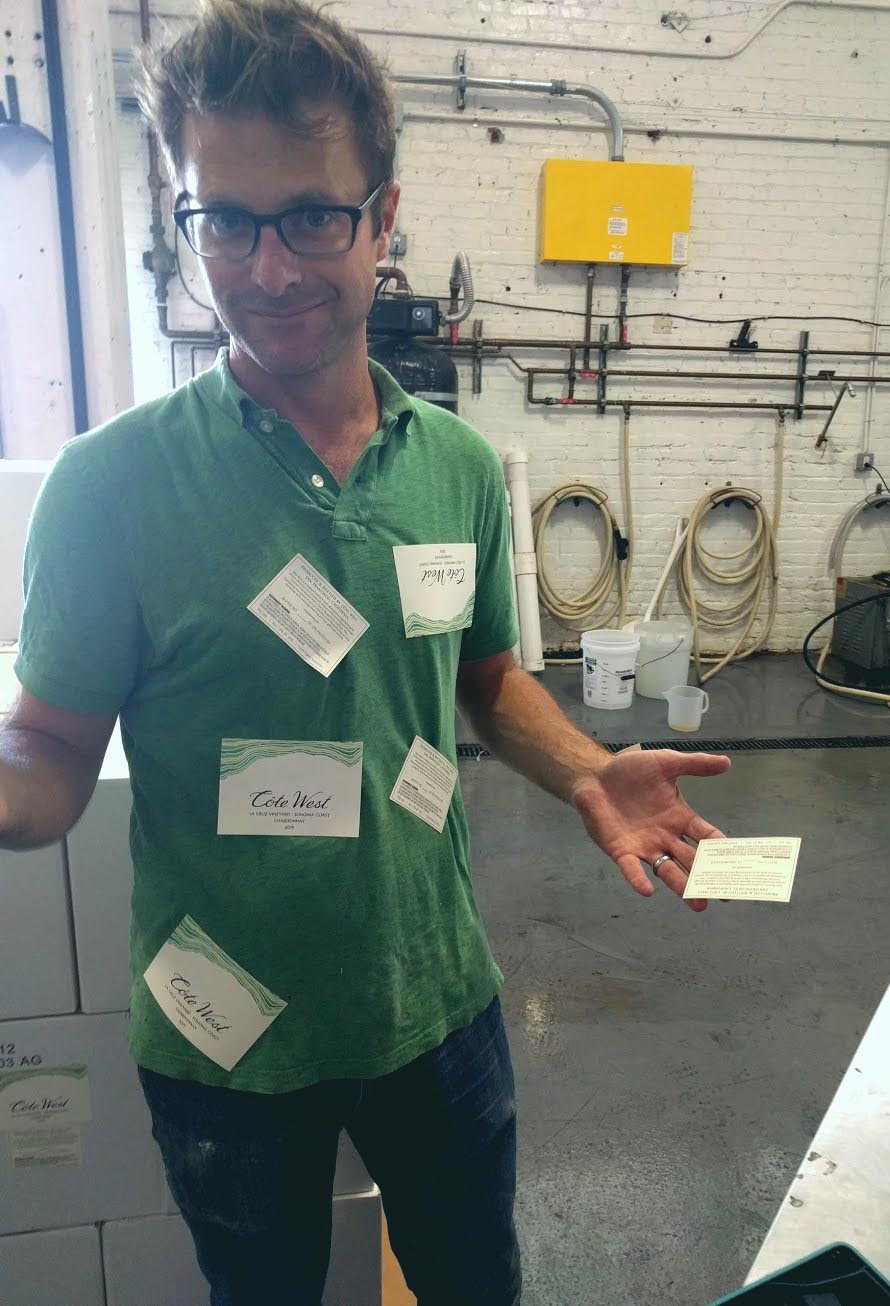

Because our wine is more Old World style, we pick grapes earlier than usual. This results in higher acid, lower alcohol, and we believe, more enjoyable wines. Choosing the exact right day to pick is a mix between art and science. We do rely on analyses like Brix (sugar content), pH, and acids, but ultimately every vineyard site has its own unique quirks which inform the decision.